Welding Habitat System

Sale and Rental of Welding Habitat System - Certified by SIRIM QAS. Welding Habitat System is designed to allow naked flame or hot work activity such as welding, grinding, cutting, to be carried out without the need for a plant/production shutdown.

Welding Habitat Systems are often associated with the offshore oil and gas industry because there is likely the presence of explosive gases or vapours. The expansion of safety awareness leads the usage of Welding Habitat System to onshore oil and gas industry, power plants and any work plant where flammable/explosive gases or vapours is very likely to present.

Our Facility/Yard

Lot 4, IKS Perbadanan Labuan, Jalan Rancha-Rancha 87000

W.P. Labuan, Malaysia

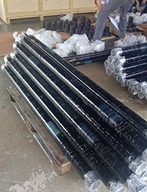

Equipment

- 1. Auto shutdown (system habitat) - 30 set

- 2. Gas Detector - 30 set

- 3. Panel - 30 set

To support the execution of the ZLNG Project (Onshore Package), our company delivers temporary office rental solutions tailored to client needs. We provide well-structured, secure, and strategically located office spaces complete with essential facilities and services. This ensures smooth coordination, effective communication, and operational efficiency throughout the project lifecycle.

- We offer RTRP piping systems that are designed and manufactured in accordance with the international codes and standards such as ISO 14692(ISO Manufacturing Standard), PDO SP 2092 (PDO Manufacturing Standard), DEP 31.40.10.19 (Shell Standard), PTS 12.34.02(Petronas Technical Standard) AWWA M45 & C950, API 15LR & 15HR and testing standards comply with ASTM D4024, D3567, D2992, D1598, D1599.

- Our Pipes and fitting are manufactured by filament winding of continuous fiberglass roving impregnated and saturated with resin on the outside of a rotating mandrel in a dual helix predetermined pattern and under controlled tension.